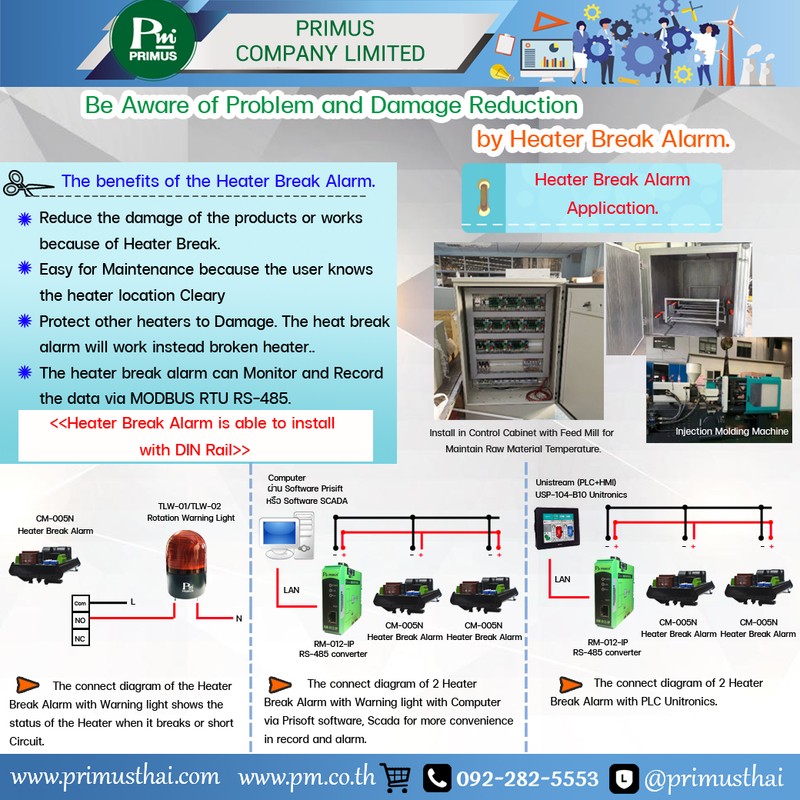

Be Aware of Problem and Damage Reduction by Heater Break Alarm

Be Aware of Problem and Damage Reduction by Heater Break Alarm.

A heater is the devices use to Heat the product, Boil the water or liquid in the industrial. Normally, the heater has a working life different on each type. If the user lacks good maintenance at a suitable time or using unsuitable power with heater will be made the heater has working like shorter than usual. We are advised in Topic: 5 Way to Use the Heater Longer but we will find the heater has abnormal decrease work time often in no reason which takes time so long to look for the cause and the heater may break before we know the cause of it. Affect to a production line or the goods and wasting to time to operate.

So, if we know about the cause in time to prevent the damage to the heater. It would be helpful to the production process and basically, users can easily and do it by themselves follow as:

- Heater Break Checking by Meter and Resistance Indicator we introduce Multimeter Model CENTER110 for measure Ohm Value in case of the heater break. The ohm will not appear but if the heater can as usual. Follow the Power Equation P=I2R หรือ P=E2/R

- Heater Break Checking by Temperature Controller with CT input. Using as bring CT hook with the wire which connect with Heater then bring CT joint with the Temp Controller directly and we have descried in How to Checking the Heater.

And the last one is using the Heat break Alarm Model CM-005N. Today, we will inside this way in topic: Be Aware of Problem and Damage Reduction by Heater Break Alarm. The Heat Break Alarm apply by measure current of heater directly. The user will know the status of Heater and fix it in time. The Heater break alarm has model as:

Heater break Checking method by (Heater Break Alarm) CM-005N

The operation of Heater Break Alarm Model CM-005N. It will check heater’s current (At max current 50 A. 4 Machine) in the same time by hook through the CT (Current Transformer) for measure the current in each heater. If the one of heater does not have current flow through. It means the Heater is broke and alarm for let the user know. In case of the output of Temperature Controller is not working but there is the current go through heater all the time because Solid State Relay Short Circuit or Contract of Magnetic Arc has closed. It will alarm for warning the irregularity.

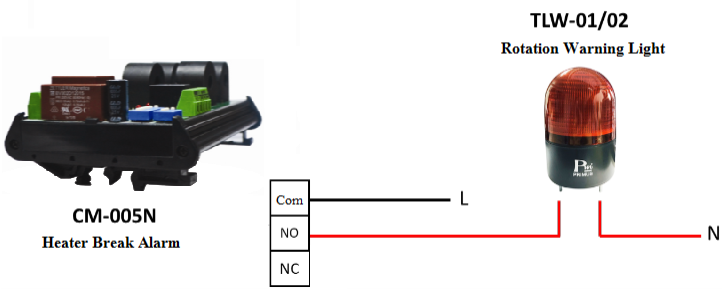

The user can bring heater alarm Model CM-005N for connect with the additional device. For made the heater break alarm faster by the connect diagram for use the heater break alarm (Heater Break Alarm) CM-005N with another device. (Picture 1).

Pic 1: The connect diagram of Heater Break Alarm Model CM-005N he connects diagram of Heater Break Alarm Model CM-005N with Digital Monitor for heater break alarm Model CM-005D.We can see the current of each heater (Maximum 8 Machine) from Display CM-005D which has install on Control Cabinet. And bring Alarm output of Heater Break Alarm Model CM-005N join with Warning Light (TLW-1/02) for Light sign for Engineer and Technician. We will know heater inside the machine break or Short Circuit.

Picture 1 the connect diagram of Heater Break Alarm Model CM-005N connect with Warning Light (TLLW-01/02) for show the heater status when break or short circuit

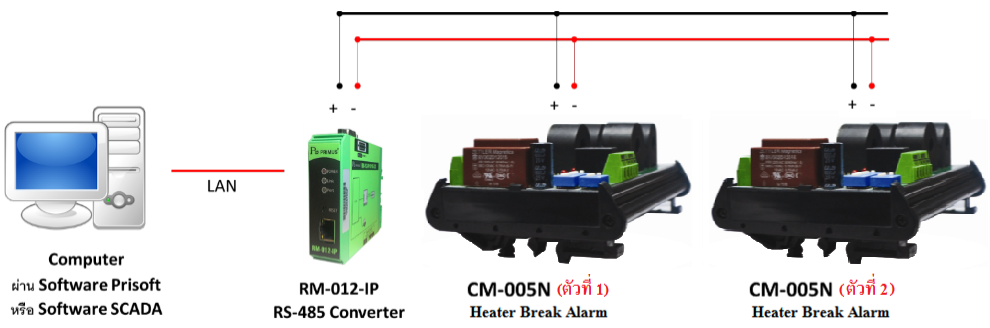

Pic 2: the connection between Heat Break Alarm Model CM-005N by Prisoft Software, Scada communicate with Computer and Converter RS485/RS232 To TCP/IP Model RM-012-IP. It can read an record the parameter from measuring in Real time via MOBUS RTU RS-485.

Picture 2 the connection diagram of 2 Heater Break Alarm Model CM-005N with Computer via Prisoft Software, Scada in Technician room easy for record or Alarm

Pic 3: the connection between Heat Break Alarm Model CM-005N with PLC (Unistream Programmable) Unitronics and Converter RS485/RS323 To TCP/IP Model RM-012-IP.

Pic 3 the connect diagram for Application of 2 Heater Break Alarm Model CM-005N with PLC (Unistream Programmable) UNITRONICS.

For the most efficiency for using the Heater Break Alarm for checking Heater. The selection of the additional device is important too. The additional device consists of Temperature Controller, Solid State Relay, Temperature Sensors such as Thermocouple, Pt100, etc.

- The benefit of Heater Break Alarm

- Decrease the damage of the product or works because of Heater Break.

- Easily to maintenance because the user knows the location of broke heater.

- Protect the affect to another heater in same machine for does not work overload instead it.

- Heater Break Alarm is able to install with DIN Rail.

The Application Example of Heater Break Alarm